FP-21T Precision 導入事例

東京大学 物性研究所 ナノスケール物性研究部門 リップマー研究室

Prototyping Printed Board Making System For thin film patterning

on SrTiO3 substrates

FP-21T Precision

XYZ resolution : 1µm

Minimum milling width : 50µm

achieved for printed board

Can we apply this for thin films on SrTiO3 substrates?

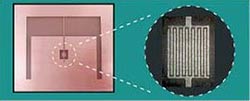

Hall bar and so on...

Difficulty No. 1

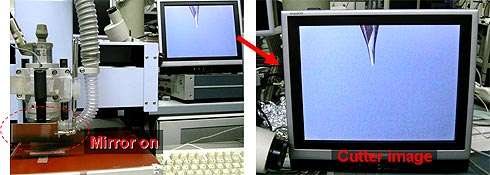

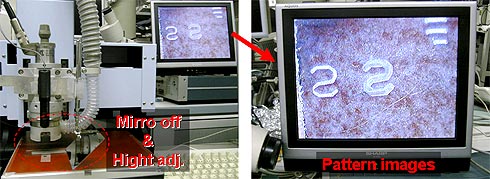

Detection of milling cutter contact with SrTiO3substrate

Printed board is conductive due to surface thick metal layer (up to 10 µm) and can be detected by electric contact.

But SrTiO3is insulator.

Even if conductive film is deposited, it is too thin for electric detection.

Image Detection

Difficulty No. 2

Milling of hard, fragile SrTiO3

Printed board is soft, which includes surface metal layer and plastic board

Milling parameters optimization

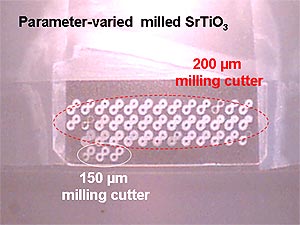

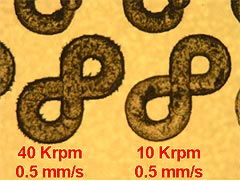

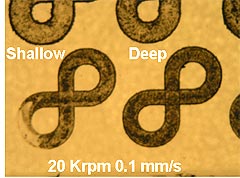

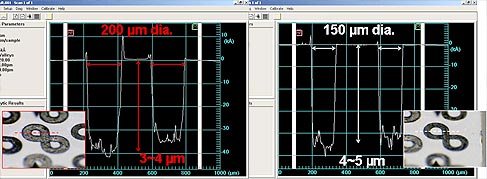

Milling parameters

| Milling cutter diameter | 50/100/150/200 µm |

| Rotation speed | from 5 to 60 Krpm |

| Milling depth | up to 5 µm |

| Lateral milling speed | from 0.1 to 2 mm/s |

etc.

きれいに加工できるのは回転数の高さではありません!

Parameters optimization summary

| Lower rotation speed is better Although too low speed is unstable to hold constant speed | Opt.: 20 Krpm |

| Depth is not so critical Although too deep results in shorter cutter life time | Opt.: up to 5 µm |

| Lower lateral milling speed is better | Min.: 0.1 mm/s |

| Milling cutter diameter dependence is unknown | Hopefully no dependence |

Parameters optimization summary

FP-21T Precision の優位性

物性研究するための手段として -

- 簡単にドライで加工できる

- フォトリソグラフィプロセスを省略できる(高価な装置がなくてもいい)

- 薬品を使わないで作成できる

- 酸化物でも加工できる

- Hall bar等が簡単に作れる

- 精度がいい

参考資料:スピンドル回転数と回転数と工具の関係